Deburring and Edge Rounding

Contact this seller for accurate pricing

-

-

-

-

+10

+10

Deburring and Edge Rounding : Ask for Price

Contact this seller for accurate pricing

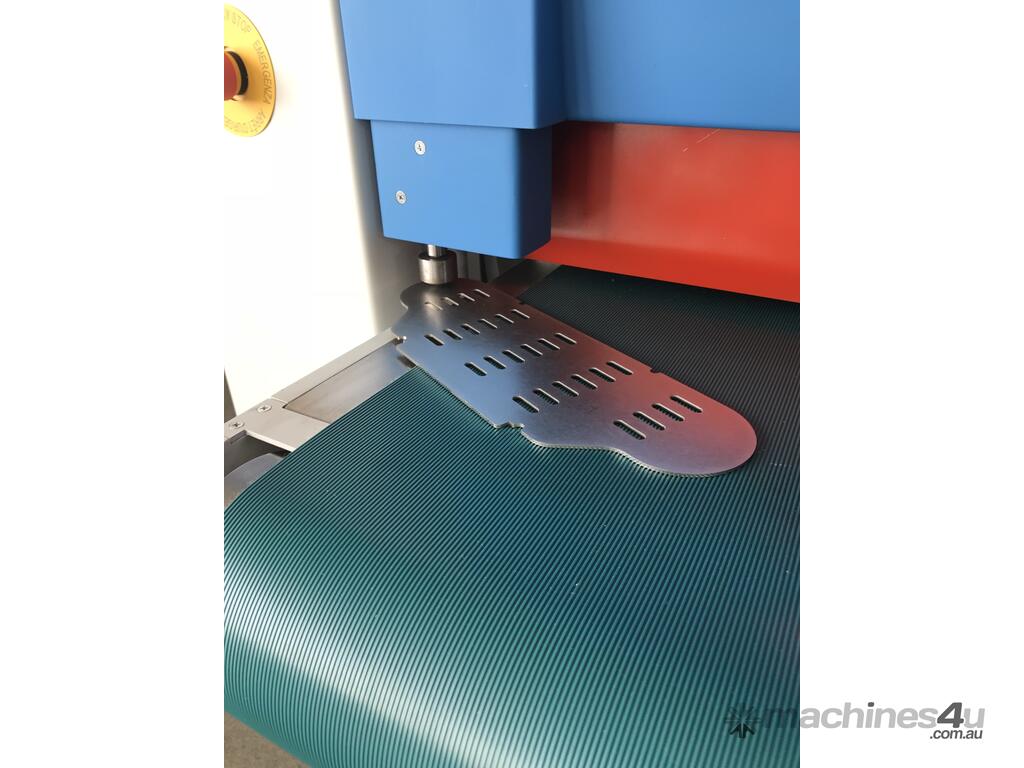

Loewer DiscMaster Series are designed to deburr and edge-round in a single pass.

Removal of burrs & splatter produced during laser, waterjet, flame and plasma cutting, or burrs in turret punch produced parts are removed in the first of a two or three step process depending on the model.

2 spindles driving abrasive discs, traverse the width of the feed through belt evenly removing the burrs before the next stage, again with 2 spindles traversing the feed through belt width produce a uniform 360deg rounded edge to all edges from all angles.

Model 4TD provides 4 spindles as described.

Model 6TD provides an additional 2 spindles creating a third row for extra processing including oxide removal etc.

Processing widths are 1,000mm , 1,500mm or (2,000mm model 4TD only)

The Loewer concept is very cost effective with uniform wear of all abrasives ensuring a low cost process with industries best results.

Parts as small as 20mm can be processed through the Disc Master as we do not require pinch rollers.

This alone provides a superior machine to other types of machine.

- Low comparable Machine Cost

- Low Abrasive Cost

- Long Life Abrasives

- Even Wear

- Excellent Deburring

- Excellent Edge Rounding

- Bonus Excellent Surface Finish

- Fast and Easy to Set Up

- Quick Changeover of Abrasives

All these advantages and a very competitive price for a German Quality Machine.

Contact this seller for accurate pricing

New Deburring Edge Rounding & Surface Finishing Machine

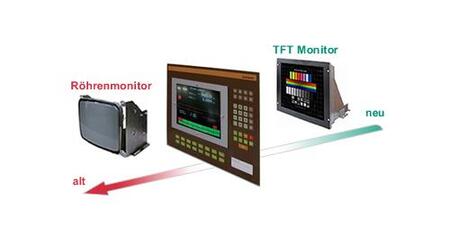

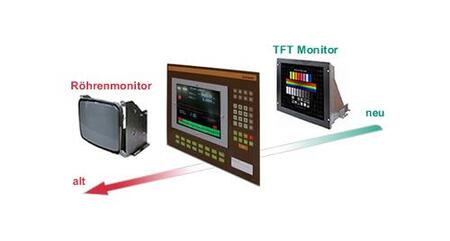

New Replacement Monitors for CNC Controls

New Corner Weld & Radius Linishing Machine

New Deburring and Edge Rounding Machine

New Cut to Length Saw Digital Position Display

New Replacement Monitors for CNC Controls

New How to Prevent Bending Die Mark and urethane replacement material

New Orbital Spin Riveting Machine

New Deburring Laser Start & Finish Joint

New Plasma Slag Deburring and Edge Rounding Machine

New Deburring and Edge Rounding Machine

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print